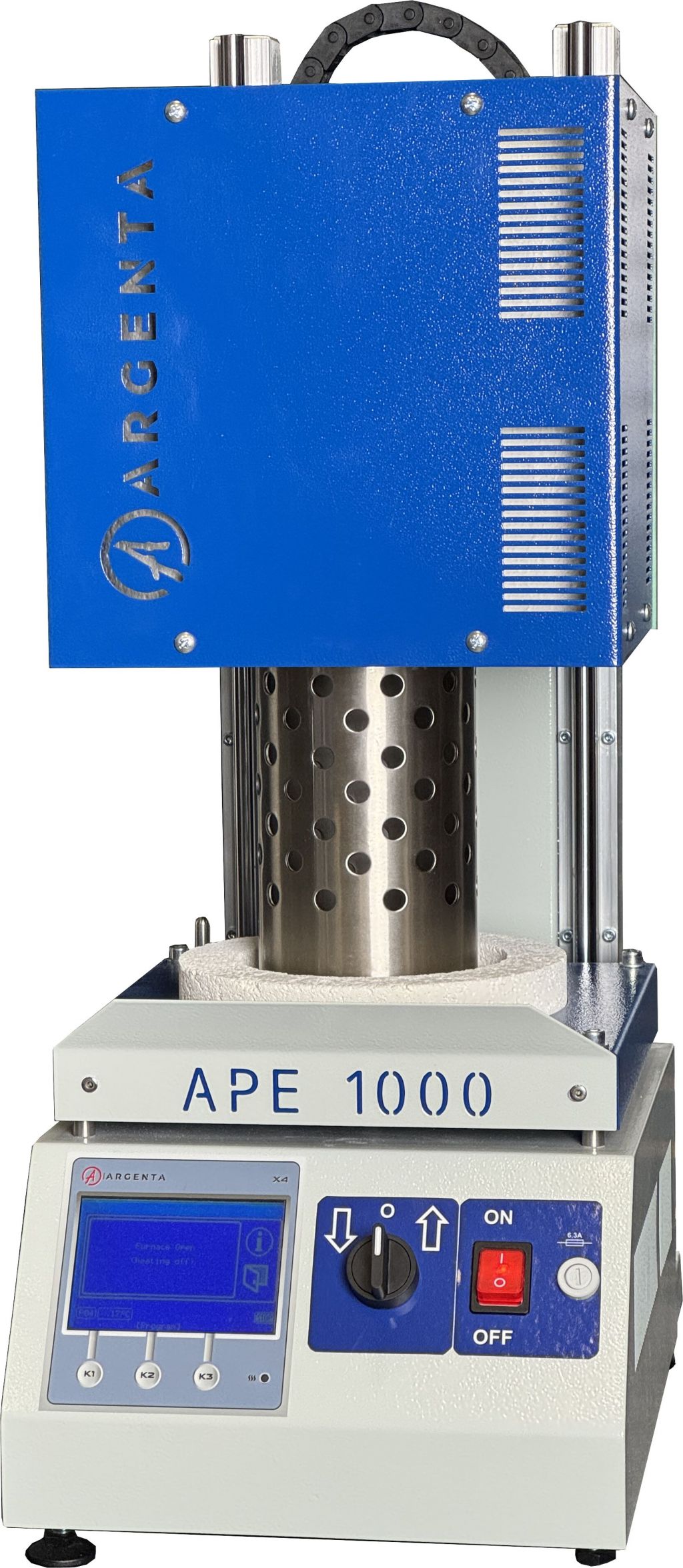

The furnace used is for burnout flask with polymers used in 3D printing. A small, cylindrical chamber and rapid temperature rise allow the polymer to burn before it swells and breaks the mass. In addition, the furnace is equipped with an installation that allows blowing air to accelerate combustion. The furnace has an electric actuator that automatically lifts the furnace chamber.

Thermal insulation is made of ecological aluminosilicate fiber. The furnace is equipped with a programmer ensuring the implementation of two different programmes, sixteen cycles each, with the possibility of setting the cycle temperature, its duration and the temperature increase. It is possible to activate a foundry programme with a delay. The programme of the controller also ensures the implementation of the programme according to the assumptions made, even in case of the failure and re-activation of the supply voltage.

The furnace can also be used for platinum casting.

*The air pump and flask support are not included in the set.

|

|

APE800

|

APE1000 | |

|---|---|---|---|

| Rated voltage: | 220-240V/50-60Hz | 220-240V/50-60Hz | |

| Rated power: | 2400W

|

1500W | |

| Maximum temperature: | 800ºC | 1000ºC | |

| Adjustable temperature rise: | 1-10ºC/min | 1-15ºC/min | |

| Number of casting programs: | 2

|

2 | |

| Cycles in program: | 16 | 16 | |

| Maximum delay in starting program: |

40 days |

40 days | |

| Inner chamber dimensions:

|

400x450x270mm | Ф120x200mm | |

| External dimensions:

|

380x300x820mm

|

260x400x670mm | |

| Weight: | 43kg

|

21kg |

|